Glass

Non-Contact Temperature Measurement in the Production Process of Glass

Glass manufacturing process demands accurate and repeatable temperature under tough working conditions.

TPS with over 20 years of experience working with world leaders like Ircon, Land and Dias Infrared and India’s leading glass manufacturing companies specialize in offering:

The DIAS infrared cameras, IR line cameras and pyrometer measure the temperatures on glass surfaces and glass melts in special spectral ranges to minimize the influence of the emissivity and so to have correct measurement results.

For more details, please visit

Glass industry | DIAS International (dias-infrared.com)

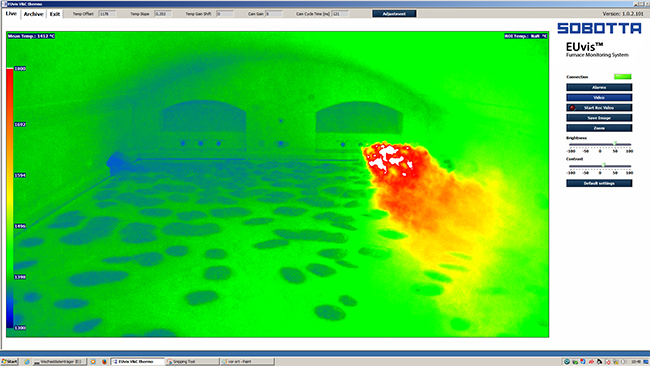

The Melt Tank cameras manufactured by SOBOTTA GmbH are the ideal solution for monitoring your processes within the melting tub. Bubbler and batch flow can be monitored visually. The temperature distribution inside the melting tub can be monitored both thermographically and by infrared technology.

For more details, please visit

Glass Industry – SOBOTTA GmbH

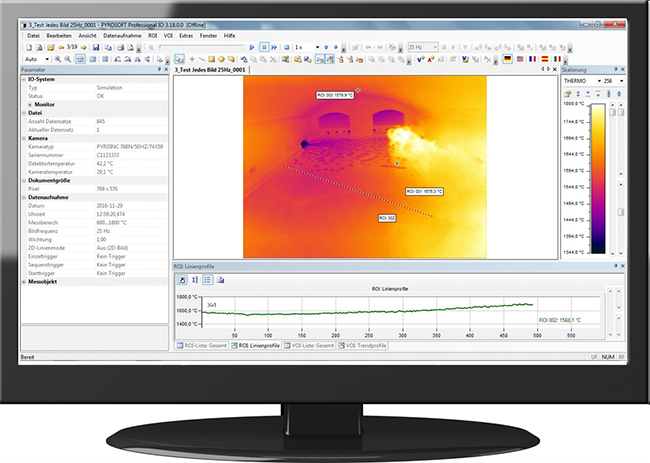

Furnace Bottom Monitoring

The glass furnaces use expensive refractory. Glass being highly corrosive in nature, the damage to refractory needs continuous monitoring. Imaging the outer shell of the melt tank with a thermal imager, especially at the tank bottom, 24×7 provides real time refractory damage. This also provides real time information on a possible glass leak.

We achieve this with our most advanced Pyroview 640L high repletion cameras and advance thermal imaging software Pyrosoft.