Encoders and sensors solutions for wind energy applications

TPS Automation: Your Trusted Partner for Encoder Solutions

At TPS Automation, we take immense pride in our longstanding partnership with Leine and Linde, a globally recognized leader in encoder technology. As their esteemed channel partner in India for over 12 years, we have been at the forefront of delivering specialized encoder solutions, particularly for wind mills.

Our expertise is not just in our years of operation, but in the depth of knowledge and commitment that our dedicated team brings to the table. Our team of experts is steadfast in their commitment to deliver high-quality service and innovative solutions that cater to your specific needs.

We understand the intricacies of wind mill operations and the critical role that encoder play in their efficient functioning. Leveraging this understanding, we provide solutions that are tailored to enhance the performance and reliability of your wind mills.

At TPS Automation, we don’t just provide products; we build relationships based on trust, quality, and a relentless pursuit of excellence. Join us as we continue to shape the future of wind mill operations with our advanced encoder solutions.

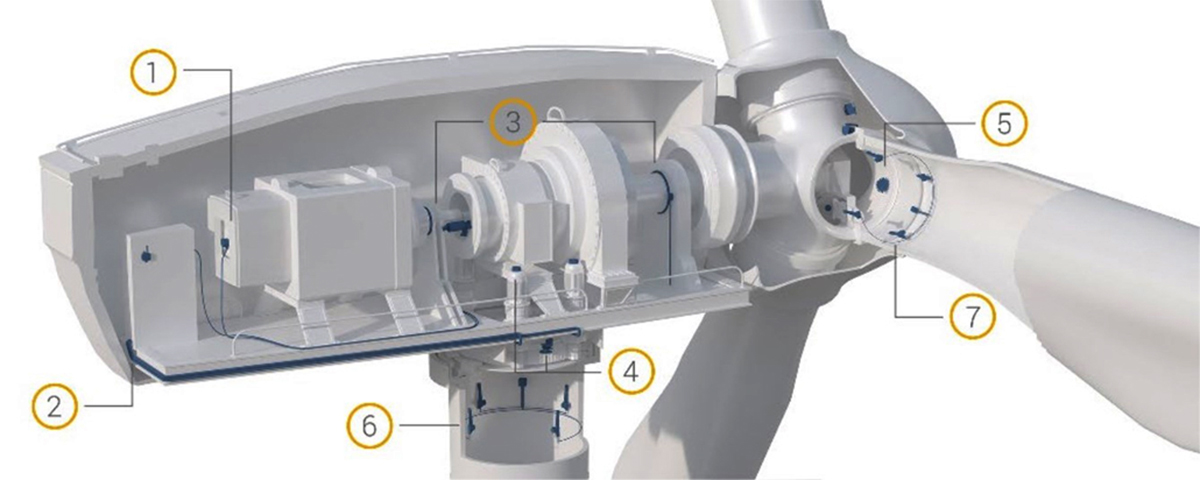

Reliable sensor solutions increase the efficiency and the lifetime of the wind power plant, which leads to a significantly lower levelized cost of energy (LCOE). Technologically advanced components made to fit – mechanically, electrically as well as with the right signals and interfaces – is enabling digitalization in the simplest way!

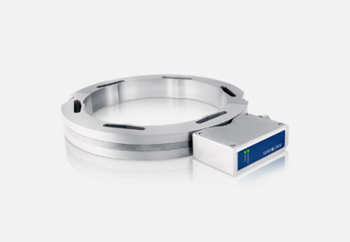

Generator encoders

The Leine Linde generator encoders are easy to install. Their product design and mounting solutions are well thought-through. For example, the Bearingless 2000 series, which are robust magnetic ring encoders with a diameter up to two meters, were developed especially for the gearless direct drives and hybrid drives of wind turbines. The encoders can be equipped with additional scanning units to enable redundancy or extra output signals if this is of use in the system. And the classic encoder model 862 is also available in the form of a dual output solution, called model 865, providing two electrically isolated output signals from one single casing.

Electrical system equipment

Fieldbus gateways, speed monitoring devices, encoder switches, signal splitters and converters are some of the electrical system equipment developed and manufactured by Leine Linde.

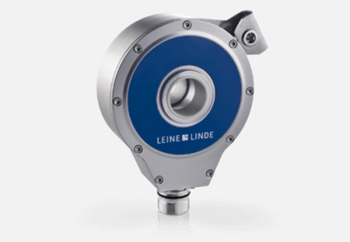

Rotor speed and position encoders

For wind turbines with gearless drives or medium-speed hybrid drives, the simplest and most reliable solution is often to measure the rotational speed by an encoder directly on the main shaft. The Bearingless 2000 series are ring encoder made to match the diameter of your shaft, up to very large sizes For slip ring-mounted encoders there are a wide range of models, sizes, and mounting accessory options available. The Leine Linde 600 series comprises both absolute single-turn and multiturn encoder models, using inductive scanning for high-resolution position readout. And the versatile 500 series contains both absolute and incremental 58 mm encoders with a multiplicity of different output signals and resolutions. All Leine Linde encoder are robust and withstand the harsh conditions to provide problem-free

service-life.

Yaw system encoders and limit switches

Leine Linde’s 600 YAWMO® and FSI 900 YAWMO® are customized encoder solutions including gears and mounting brackets. In both the 600 series and the 900 series, we focus on a specific technology for even greater resistance, working even in the most difficult conditions, such as the inductive scanning method and optimized ball bearings to increase the service lives of the encoders.

The FSI 900 YAWMO®, with limit switches, has certified safety functions in accordance with the machinery directive (2006/42/EG) and IEC 61400. For functional safety needs, we can help you find a product designed for the exact application.